大功率研磨泵机组应用于年产35万吨ABS树脂工程

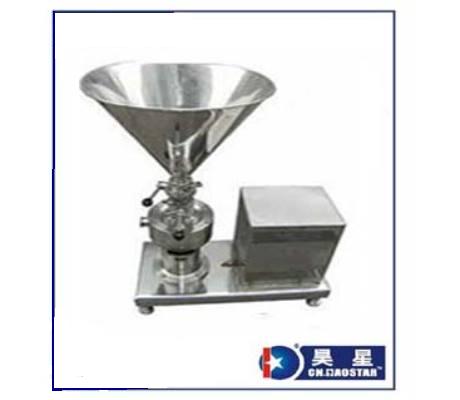

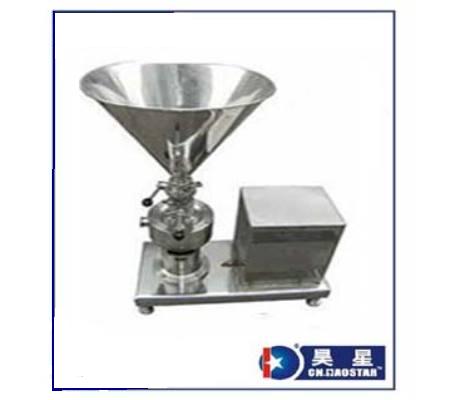

昊星75kw大功率研磨泵机组(又称特大型研磨泵、管道胶体磨、管线式研磨泵、管道磨)应用于陶氏化工、台湾丰宏和科元ABS树脂是丙烯腈-苯乙烯-丁二烯共聚物的生产工程项目,目前,科元新材料每年生产能力达到35万吨ABS(Acrylonitrile Butadiene Styrene),ABS是一种强度高、 韧性好、易于加工成型的热塑型高分子材料。ABS树脂结构是由丙烯腈(Acrylonitrile)、1,3-丁二烯(Butadiene)、苯乙烯(Styrene)三种单体的接枝共聚物。它的分子式可以写为(C8H8·C4H6·C3H3N)X,但实际合成反应时往往是含丁二烯的接枝共聚物与丙烯腈-苯乙烯共聚物的混合物,其中,丙烯腈占15~35,丁二烯占5~30,苯乙烯占40~60,常见的比例是A:B:S=20:30:50,此时ABS树脂熔点为175℃。 随着三种成分比例的调整,树脂的物理性能会有一定的变化: 1,3-丁二烯为ABS树脂提供低温延展性和抗冲击性,但是过多的丁二烯会降低树脂的硬度、光泽及流动性; 丙烯腈为ABS树脂提供硬度、耐热性、耐酸碱盐等化学腐蚀的性质; 苯乙烯为ABS树脂提供硬度、加工的流动性及产品表面的光洁度。ABS树脂性质是微黄色固体,有一定的韧性,密度约为1.04~1.06 g/cm3。它抗酸、碱、盐的腐蚀能力比较强,也可在一定程度上耐受有机溶剂溶解。我公司大座胶体磨型研磨泵用于广西科元新材料有限公司35万吨年产ABS树脂、陶氏化工和奇美实业是世界上大的ABS树脂生产商,这些用户其中科元公司与台湾宏丰开发年生产35万吨ABS树脂占有在台南及镇江的工厂每年大约生产130万吨ABS树脂之25比例以为大型生产工厂。其他主要的ABS树脂生产厂商包括:拜耳化工、LG化学、GE塑料、巴斯夫等。 昊星大功率研磨泵机械结构、大流量、输送扬程和高速将橡胶块料的丙烯腈-苯乙烯共聚物(AS)与聚丁二烯(B)混合,或这将两种胶乳研磨、混合细化后再共聚; 在聚丁二烯胶乳中加入丙烯腈及苯乙烯单体进行接枝共聚。 ABS树脂可以在-25℃~60℃的环境下表现正常,而且有很好的成型性,加工出的产品表面光洁,易于染色和电镀。因此它可以被用于家电外壳、玩具等日常用品。常见的乐高积木就是ABS制品。 ABS树脂可与多种树脂配混成共混物,如PC/ABS、ABS/PVC、PA/ABS、PBT/ABS等,产生新性能和新的应用领域,如:将ABS树脂和PMMA混合,可制造出透明ABS树脂。 生产 ABS有两种主要的工业生产方法: 将丙烯腈-苯乙烯共聚物(AS)与聚丁二烯(B)混合,或这将两种胶乳混合后再共聚; 在聚丁二烯胶乳中加入丙烯腈及苯乙烯单体进行接枝共聚。 生产1公斤ABS树脂需要的原料和能源大约相当于生产2公斤石油。分散、应用在ABS树脂中,橡胶颗粒呈分散相,分散于SAN树脂连续相中。当受到昊星研磨机(管道胶体磨)复杂研磨和高速旋转剪切碾碎的冲击时,交联的橡胶颗粒承受并吸收这种能量,使应力分散粉碎,解聚均质乳化,超微粒粉碎从而阻止裂口发展,以此提高抗撕性能。

CN.HAOSTAR研磨机(大型管道磨-管线式研磨泵)能快迅瞬间有效使接枝共聚合的目的在于改进橡胶粒表面与树脂相的兼容性和粘合力。这与游离 SAN树脂的多少和接枝在橡胶主链上的 SAN树脂组成有关。这两种树脂中丙烯腈含量之差不宜太大,否则兼容性不好,会导致橡胶与树脂界面的龟裂。 使用研磨泵生产的高品质ABS树脂可用注塑、挤出、真空、吹塑及辊压等成型法加工为塑料,还可用机械粘合、涂层、真空蒸着等法进行二次加工。由于其综合性能优良,用途比较广泛,主要用作工程材料,也可用于家庭生活用具。由于其耐油和耐酸、碱、盐及化学试剂等性能良好,并具有可电镀性,镀上金属层后有光泽好、比重轻、价格低等优点,可用来代替某些金属。还可合成自熄型和耐热型等许多品种。

由此可见,温州昊星机械设备制造有限公司研制的用于ABS树脂大功率研磨机(特大型研磨机又称管道胶体磨、一管线式研磨泵、管道磨)适用于不论是溶剂性ABS树脂、热塑性聚氨酯、催化剂、石墨烯和油性本硅消泡剂、密封胶、胶粘剂、阻燃材料及水性改性沥青、水玻璃(白炭黑,二氧化硅)、消光剂、发泡剂、药辅料等化学食品制药工程项目上,以适应各种用途。主要产品覆盖了防水材料、阻燃剂、消光剂、发泡剂、消泡剂、催化剂、石墨烯、纳米红维、润滑油脂、化工、胶囊、生物化工、精细化工、水处理、污水处理、垃圾处理、硅酮玻璃钢、水玻璃、胶粘剂、油水乳化、乳化硅油、石墨烯、化肥、鱼虾酱、番茄酱、色拉酱等各类流体、胶体料浆和膏体等物料得到高速分散、搅拌混合、解聚均质、研磨细化。企业科研的科研中试和生产装备,受到广大用户好评和青睐。大展身手。欢迎广大用户咨询微信号13857776588/QQ601537841.

应用案例:智能低温胶体磨组合设备JM-FBF140-2Z应用台湾上工植物原生态研磨粉碎制剂工程;JM-W300AC55KW纳米锥体磨-石墨烯研磨机应用于贵州鼎玺烯材高科技有限公司是国内年产量100吨石墨烯生产线;JM-W200AB-F泵型管线式耐高温210Cº多功能研磨机应用于嘉兴北化年产量6000吨新型防老剂SPPD、多功能流动剂LT-13、交联剂、无锌化活性剂等研磨分散粉碎精细处理和金山化工模量增强剂HMZ、均匀剂A78等橡胶助剂项目;耐腐蚀耐磨特殊钢精制JM-W250AD37型应用OSC Siam Silica CO.,Ltd.、美国陶氏、上海凯赛、中国林业科学研究院林产化学工业研究所江苏强森生物能源成果转化项目活性炭、碳酸钙等水处理材料项目工程;JM-W250AD-2/4应用于中海亚化学年生产3000吨吸附式调温材料项目和中石化北京燕山催化剂厂、杭州凯明催化剂股份等催化剂化工工程项目;JM-W180AC用于东莞钻脂、中石化重庆分公司、一坪润滑油、纳拓(上海)润滑技术的合成脂制备;JM-WB300AB多功能研磨机、WB250AB-2(卫生级泵式)系列应用嘉必优万吨生物工程ARA+DHA(发酵法)单体工厂;海圣鱼粉厂粉碎鱼虾浆,亚泰蕃茄酱和辣椒酱及化肥大型生产线;华宇炭黑、黑猫,双龙,立安东,泰国硅暹,吉清等改性白炭黑大型打浆泵用于年产5年吨二氧化硅滤饼高速制浆改性研磨工程项目;JM-W200AB22系列高剪切多功能研磨机泵应用于年产2万吨佳莹,新旺,巴斯伏阻燃材料工程;JP-W200AC管道胶体磨、JP-W250A55系列管道磨式10台大型研磨泵成功应用于年产8万吨四新高碳醇&有机硅乳液设备组,消泡剂设备组等工程项目;JP250AD-F分体式研磨泵和大型胶体磨JM-W250AB、W250AD-2系列钛白研磨机应用在东方钛业、攀钢渝钛、东佳集团、大互通钛业、中国钛海集团、惠云钛业、兴茂钛业、金龙钛业、海峰鑫化工、金浦集团南京钛白化工等公司的多条年产4-20万吨精钛粉(钛渣)制取改性钛白(二氧化钛)包膜的中端制备;多台JM320AD-2/75Kw大功率研磨机泵型使用在科元年产35万吨ABS橡胶树脂生产工程石化项目。以及涉及南海霸力化工、上海汇润胶粘剂、福尔波粘合剂(广州)、江阴贝瑞森生化技术、永得利胶囊、钱江胶囊、中亚胶囊、浙江绿健胶囊、康恩贝集团、仙琚药业、新昌制药、中柴新能源有限公司、中国橡胶集团特种材料研究所等胶粘剂、化学试剂、医药制剂等项目工程。昊星机械设备在管道联接密闭性好,使含颗粒高效迅速分散解聚、搅拌混合、打浆均化、研磨粉粒和输送自动一体化工艺处理上有了更大发挥,与类似产品比较在其节能和生产效率的数倍,效益显著,与类似产品比较在其生产效率的数倍,可大幅度的降低生产成本费用,而且颗粒均匀、清洗换色方便、无研磨杂质等性能。

Company Profile

Wenzhou Haostar Machinery Equipment Manufacturing Co., Ltd. CN.HAOSTAR® has 30 years of experience in cutting, pulverizing, stirring, depolymerizing, dispersing, mistar, emulsifying, homogenizing, peeling, crushing, grinding and other high-end machinery for fluid material particles. The equipment researches and develops, designs and manufactures high-tech SMEs, and builds the leading brand in China's colloid mill pump industry. In order to adapt to the new trend of wisdom, it will help to gather talents, enhance independent innovation capability, develop new industries, strengthen first-hand trials, effectively exert reform and innovation, and move to the national independent innovation demonstration zone in the high-end equipment manufacturing industry cluster in southern Zhejiang-Wenzhou The company was established in the Binhai Park of the Economic and Technological Development Zone. The park faces the East China Sea, shoulders Luoshan, neighboring university towns, Sancha wetlands, places of interest and historical sites, dotted with beautiful scenery. It is located at the sea, land and air transportation hub: Longwan International Airport, Wanneng Wharf, and the railway station. High-speed double-line export, Jingkai Logistics Park, convenient transportation. The company is committed to design, development, manufacturing, processing: colloid mill, grinding machine, mixer, homogenizer, grinding pump, imported equipment, non-standard supporting machinery maintenance and development. Dedicated to Zhejiang, Shanghai, Jiangsu, Tianjin, Shandong, Henan, Guangdong, Inner Mongolia, Hunan, Xinjiang, Hebei, Beijing and other provinces and cities and Taiwan, Hong Kong, Macao Special Administrative Office, and exported to Germany, France, Singapore, Vietnam, Pakistan India, Thailand, Italy, the United States and other countries provide services to users in more than 140 countries and regions around the world.

CN.HAOSTAR® company is a member of China Invention Association, China Quality Supervision and Inspection Association, China Food and Packaging Machinery Industry Association, Wenzhou Electromechanical Technology Association, Food and Pharmaceutical Machinery Industry Association, China Food and Pharmaceutical Machinery Production Base, etc. Products CE, ISO9001 certification, implementation Q/ WHX0 and other enterprise standards, national standard JB and international standards, since 2000, more than 40 patent certificates, titanium white fine continuous grinding machine won the scientific and technological achievements of Zhejiang Province, graphene liquid fine processor design system, silica modification Pulp design system, development zone scientific and technological achievements reward, and won the "good faith unit" of China's food packaging and machinery industry, national quality inspection and stable qualified products, Wenzhou electromechanical industry "scientific and technological innovation enterprise", "star entrepreneur", China quality inspection Advanced units and advanced individual members of the Association, Wenzhou Electromechanical Technology Industry Experts, Member of Mechanical and Electrical Engineers Committee, Wenzhou Economic and Technological Development Zone Science and Technology Innovation Enterprise, Wenzhou Innovation Technology Enterprise, Zhejiang Science and Technology Achievement Award, Zhejiang Industrial New Product, Zhejiang Province Honorary titles such as technology-based SMEs.

For 30 years, our company has long been engaged in high-efficiency wet grinding technology and intelligent manufacturing machinery and equipment industry with high shear dispersion, emulsification, homogenization, mistar and mistar systems. All equipments are tailor-made for customers, including laboratories. Industrial production and complete sets of equipment, patents and technology projects with many equipment processes. With strong resource integration and application capabilities, strong R&D capabilities, extensive global marketing network, strong financial strength and project financing capabilities, it has formed a complete industrial chain covering design, R&D, manufacturing and international trade. Industrial value and market competitive advantage. The company is committed to the design, development, manufacture, processing and sales of food machinery equipment, chemical machinery equipment, pharmaceutical machinery and equipment: vertical colloid mill, pipeline colloid mill, reflux colloid mill, closed colloid mill, split colloid mill, lying Colloid mill, low temperature colloid mill, high temperature grinder, titanium white grinding pump, white carbon black beating pump, shear colloid homogenizer, high shear mistar homogenizing pump, dispersing grinding pump, crushing pump, wear resistant corrosion resistant grinding pump , high-speed beating pump, white wine smasher, graphene grinder, high-shear grinder, multi-functional homogenizing grinder, emulsifier, disperser, gouache mixer, beater, pipe mill, emulsified homogenizing pump, colloid Pump, high shear disperser, high efficiency emulsified mistar pump, screw pump, pneumatic slurry pump, mistar pump, high shear dispersing emulsification pump, automatic tank washer, water treatment equipment, concentration equipment, filtration equipment, sandwich pot, cold Hot cylinders, reactors, fermenters, storage tanks, batching tanks, valve fittings and electromechanical products, product service areas covering industrial, agricultural, transportation, energy, construction, light industry, automobiles, ships Important national economic industries and emerging technology applications such as key laboratories of ships, mines, metallurgy, aerospace and university research institutes.

CN.HAOSTAR® technical department personnel make full use of the innovative advantages of all aspects of proprietary property rights and patent science and technology. The pipeline-type multi-functional grinding machine has obtained the project of scientific and technological development project. The titanium-white micro-continuous grinding machine has obtained the scientific and technological achievements of the Science and Technology Department of Zhejiang Province. The grade grinding pump and the intelligent low-temperature colloid mill fill the blanks at home and abroad. The high-tech project has been mass-produced by our company's research and conversion industry. Intelligent new products such as: intelligent low-temperature colloid grinding equipment, automatic gouache mixed emulsion grinding coating complete equipment, high efficiency Liquid-liquid mistar complete engineering equipment, graphene nano-cone mill, pipeline colloid mill, titanium white carbon black grinder, colloid homogenizer, nano-scale grinding pump, high-efficiency mixer, grinding type crushing pump, dispersion grinding machine, New products such as distiller's grains clean energy pulverizing unit, high carbon alcohol & silicone emulsion product equipment, group body defoamer equipment group, cross-linked silicone grease equipment group. As we all know, in the past, in order to meet the needs of industrial development more quickly, China has purchased a large number of foreign advanced new or second-hand imported equipment. However, since September 2008, the US “subprime mortgage crisis” has actually evolved into a global “crisis”. This crisis has become a very important event in the past 10 years and has a profound impact on the global economy. To this day, the global economy is paying for this crisis. In recent years, the manufacturing industry is shrinking, and the production and processing costs have risen sharply. In particular, the prices of some imported equipment spare parts are beyond the scope of the enterprise, and the import of spare parts for imported equipment is complicated and long-term, and imported equipment is used. Many of the components have been exhausted and aging, and imported equipment will inevitably lead to failures of leakage and leakage, and the replacement cycle of imported spare parts will be invisible or unsuccessful. In order to ensure the normal operation of the equipment and reduce the maintenance cost, a good method is to achieve localization transformation of imported equipment.